Performance and efficiency made for you

SKANDI KRAFT®

iTECH TIG 220 AC/DC

iTECH TIG 220 AC/DC

The advanced iTECH TIG 220 AC/DC with an innovative TIG AUTO option – once the material type and thickness are entered, it sets the appropriate welding parameters and ensures that the machine is ready to use. Semi-pro and amateur welders will never regret the iTech, since they can focus on their technique instead of the settings.

This is the machine of choice for those seeking excellence in welding. It has a 3.5″ LCD display, allowing intuitive and easy operation in 4 languages. Used for HF-TIG, LIFT-TIG and MMA welding. Its compact size and weight of 14.8 [kg] make it mobile, portable and comfortable to use, thanks to the transport handle. It offers a comfortable, quiet operating mode (FAN STOP) with more energy savings.

The iTECH TIG 220 AC/DC comes with an innovative airflow system NorthernWind (NW), through the cooling chamber boosting the life, durability and duty cycle of the components.

The iTECH TIG 220 AC/DC is ideal for welding materials with a thickness of from 0.1 [mm] to 6 [mm]:

- in metalshop work (air conditioning pipes, oil sump, exhaust manifolds),

- at the company (aluminium structures, radiators/intercoolers, wheel rim repair),

- light industry (sanitary installations, aluminium trusses, HSS surfacing).

AUTO TIG SETTING MODE

user-friendly, SMART welding control

AUTO TIG SETTING MODE

user-friendly, SMART welding control

NORTHERNWIND (NW)

true innovation in extending

lifespan & durability

MODE SELECTION

more methods – better choice

MODE SELECTION

more methods – better choice

FAN STOP MODE

FOR LOW NOISE

FAN STOP MODE

FOR LOW NOISE

PULSE MODE

for better effect and comfort of work

PULSE MODE

for better effect and comfort of work

Precise control of the welding arc

High efficiency Heavy Duty: 60% at 40C; 200A

RESELLERS

iTECH TIG 220 AC/DC

FULL SPECIFICATIONS

The advanced iTECH TIG 220 AC/DC with an innovative TIG AUTO option – once the material type and thickness are entered, it sets the appropriate welding parameters and ensures that the machine is ready to use. Semi-pro and amateur welders will never regret the iTech, since they can focus on their technique instead of the settings.

This is the machine of choice for those seeking excellence in welding. It has a 3.5″ LCD display, allowing intuitive and easy operation in 4 languages. Used for HF-TIG, LIFT-TIG and MMA welding. Its compact size and weight of 14.8 [kg] make it mobile, portable and comfortable to use, thanks to the transport handle. It offers a comfortable, quiet operating mode (FAN STOP) with more energy savings.

The iTECH TIG 220 AC/DC comes with an innovative airflow system NorthernWind (NW), through the cooling chamber boosting the life, durability and duty cycle of the components.

Above all, the machine provides intuitive operation and advanced functionality that allows individual adjustment of settings in HF-TIG, LIFT-TIG modes. Choice of DC welding mode (black steel, SS stainless steel, titanium) or AC (aluminium and its alloys). Can weld with PULSE with full adjustment of: frequency, cycle, current in DC; and balance and frequency in AC. It has a proprietary AC AUTO mode which, after setting the parameters, automatically adjusts the frequency and balance of the pulse in AC. A choice of 6 AC waveforms will improve the precision of your work It has options for 2T and 4T operation. The machine has also been equipped with the SPOT feature, which is particularly useful for overlapping thin sheets and pre-grafting before butt welding.

A 3 m all-copper 3×2.5 [mm2] power cable, a 3 m all-copper 25 [mm2] ground cable and a 3 m electrode holder are provided with the machine. The iTECH TIG 220 AC/DC comes with a TIG SR26 torch of 4 metres so the welder to be controlled from the handle. The torch has a flexible body (Flex) with a laminar lens (supplied: 1.6, 2.0, 2.4 [mm]) ).

The iTECH TIG 220 AC/DC is ideal for welding materials with a thickness from 0.1 [mm] to 6 [mm]:

- in metalshop work (air conditioning pipes, oil sump, exhaust manifolds),

- at the company (aluminium structures, radiators/intercoolers, wheel rim repair),

- light industry (sanitary installations, aluminium trusses, HSS surfacing).

Basic info about the SKANDI KRAFT iTECH TIG 220 AC/DC

- TIG AC/DC AUTO system – after specifying the type and thickness of the material, it can auto adjust the welding parameters in the HF-TIG method.

- Welding with 4 methods: TIG AC/DC AUTO, TIG (AC/DC) HF and LIFT-TIG, MMA using a consumable electrode.

- PULSE welding, in this function the welder can fully adjust the parameters, change the focus of the arc and shape of the joint.

- Unique among automatic welders in Europe, it’s the first and only one on the market with a choice of 6 AC waveforms (rectangular, sinusoidal, triangular, front triangular wave, rear triangular wave, trapezoidal).

- Rectangular – loud and efficient for welding thick aluminium-aluminium alloy parts.

- Sinusoidal – gentle and provides smooth arc guidance in both thick and thin materials.

- Triangular – suitable for welding thin materials due to the short base current time.

- Front&Rear triangular wave – proprietary option to use the triangular wave to a greater extent

- Trapezoidal – hybrid wave, a combination of sine and rectangular.

- TIG SR26 torch with potentiometer to adjust current from the handle, featuring lenses to reduce gas consumption and improve weld quality.

- A welder with an easy-to-read 3.5″ LCD display, four selectable languages and 18 memory channels to save settings.

- The FAN STOP system rests the fan at idle – so the welder is quiet when powered up and fully functional, saves energy and reduces dust in the system. The fan automatically switches on when welding starts.

- The LIFT-TIG function, equipped with the SOFT START module, for no risk of damaging the electrode when starting the welding process. For welding under demanding conditions (without an ioniser)

- It’s built with high performance IGBT transistors.

- Mobile and versatile with a transport handle. Welder for pro and semi-pro use.

Welder functions

TIG AUTO welding

- Automatically adjusts the welder after specifying the type of material and thickness, the machine adjusts the welding parameters. This system has the option of manually tuning the welding current for individual parameter selection.

- The AC or DC mode is set automatically depending on the type of material.

TIG AC/DC method (HF/LIFT)

- Choice of AC and DC welding modes

- AC – alternating current mode, for welding aluminium alloys.

- DC – direct current mode, for welding black steel, stainless steel (chromium-nickel) and other materials.

- PULSE – in this function, the welder can fully adjust the machine parameters, the focus of the arc and shape of the joint.

- Choice of 6 AC waveforms (rectangular, sinusoidal, triangular, front triangular, rear triangular, trapezoidal)

- BI LEVEL – a function that allows seamless switching between two welding current values. Activated with a quick press of a button on the torch, it allows the current to be changed without interrupting work. It is particularly useful when welding continuous welds on materials of different thicknesses, as well as in situations where welding current control is required, for example when welding aluminium, for better temperature control.

It has 2T and 4T options – to start the gas flow before arc ignition when the button is pressed. When the button is released, the unit starts a preset ramp-up to the base current. Pressing the button again drops the current, extinguishes the crater and discharges gas.

It has adjustable parameters for TIG AC/DC welding:

- gas outflow before ignition [s],

- welding start current [A],

- current ramp-up time [s],

- peak current (welding current) [A] A,

- pulse cycle [%],

- pulse frequency [Hz],

- base current (only in AC mode),

- current falling time [s] seconds,

- final current/crater extinction [A],

- post-process gas discharge [s] seconds,

- AC pulse balance [%],

- AC pulse cycle [Hz].

MMA welding

- Hot Start – boosts the start of welding by temporarily increasing the welding current at the start.

- Arc Force – adjusts the length of the welding arc, making it possible to reduce or increase the depth of fusion and reduce spatter.

- VRD – turns off the arc when the electrode detaches from the material for a safer welding environment.

- Anti Stick – makes it easier to detach the electrode if it sticks.

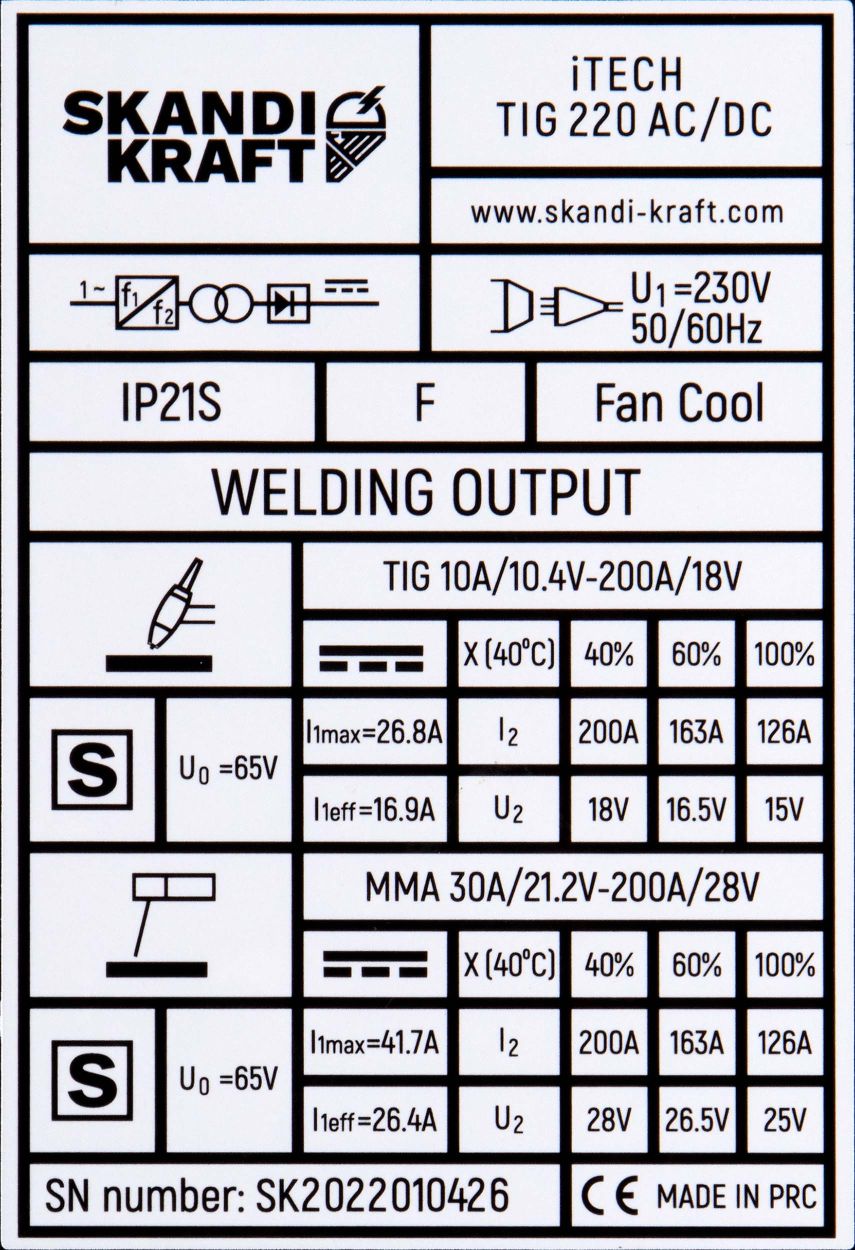

Technical data

POWER SUPPLY PARAMETERS

- Power supply: 230 V

- Frequency: 50/60 Hz

- Idling voltage: 65 V

TECHNICAL PARAMETERS

- TIG welding current: 10-200 A

- TIG welding voltage: 10.4-18 V

- Efficiency (at 40°C):

- 40%/ 200 A / 18 V

- 60%/ 163 A /16.5 V

- 100%/ 126 A / 15 V

- MMA welding current: 30-200 A

- MMA welding voltage: 21.2-28 V

- TIG efficiency (at 40°C):

- 40%/ 200 A / 28 V

- 60%/ 163 A / 26.5 V

- 100%/ 126 A / 25 V

TIG AC/DC PARAMETERS

- PRE GAS: 0-1 [s]

- welding start current START AMP: 10-200 [A]

- UP SLOPE current rise time: 1-15 [s]

- PEAK AMP peak current: 10-200 [A].

- AC balance: 10-90 [%]

- DOWN SLOPE falling time: 0-25 [s].

- end current: 10-200 [A]

- POST GAS discharge: 0-10 [s].

- Pulse frequency: 0.5-200 [Hz].

- Pulse cycle: 5-95 [%].

PHYSICAL CHARACTERISTICS

- Length x width x height: 48 × 21 × 38 [cm].

- Weight: welding machine [net] 14.8 kg, in a carton [gross] 21kg

- Degree of housing protection: IP21S

- Cooling: fan

ADDITIONAL FUNCTIONS

- PULSE fully adjustable parameters: yes

- FAN STOP switching off the fan at rest: yes

- 2T/4T for more comfortable creation of longer welds: yes

- VRD voltage reduction and improved safety in MMA: yes

- Arc Force adjustment of welding arc length: yes

- Hot Start rapid arc ignition: yes

- Anti Stick prevents electrode sticking: yes

- Quick connector for gas hose connection (TYPE 21): yes

- memory channels: 18

- SKANDI KRAFT iSIMPLE TIG 220 AC/DC welder with integrated 3 metre long 3×2.5[mm^2] power cable.

- TIG torch SR26 Flex 4 metres with control from the handle.

- All-copper ground cable 3 metres, cross-section 25[mm2].

- Copper electrode holder 3 metres, cross section 25 [mm2].

- 3 laminar gas lenses (1.6; 2.0; 2.4 [mm]).

- 3 diameter tungsten electrodes (1.6; 2.0; 2.4 [mm]).

- 3 connector plugs (long, medium, short).

- 3 x collet (1.6;2.0;2.4 [mm] ).

- 1 x lens insulator.

- 3 x ceramic nozzle “8”.

- Gas cylinder mounting components: 2 x gas regulator mounting clamps, 2 metre gas hose, instructions, spanner, Allen.

- Instructions