Focus on your bead, speed and ease of use

SKANDI KRAFT®

iTECH MIG 280 4R

iTECH MIG 280 4R

The iTECH MIG 280 4R 3-in-1 welder is used in primarily in light industry. With the innovative MIG/MAG AUTO system, once the material, thickness and wire diameter are entered, the unit selects optimal settings and is ready to go. It also has a MANUAL settings mode for metalshop masters and pro welders. Semi-Pro and amateur welders will never regret the iTech, since they can focus on their technique instead of the settings. The machine is on a rugged cart with swivelling castors and enough room for 50L cylinders to be safely moved.

The iTECH MIG 280 4R has an innovative system of air flow through the cooling chamber NorthernWind (NW), boosting the life, durability and duty cycle of the components.

The iTECH MIG 280 4R is ideal for welding materials with thicknesses

from 0.5 [mm] to 23 [mm]:

- light industry (aluminium structures, stainless steel tanks),

- in the metalshop (welding of half-shafts, welding of balustrades),

- at home (repair of backhoe blades, manufacture of gates and fences).

AUTO SETTING MODE

user-friendly, SMART welding control

AUTO SETTING MODE

user-friendly, SMART welding control

ROBUST FRAME & MOBILE CART

SINGLE AND DUAL PULSE

for better effect and comfort of work

SINGLE AND DUAL PULSE

for better effect and comfort of work

NORTHERNWIND (NW)

true innovation in extending lifespan & durability

EASY WIRE CHANGE ON THE FOUR-ROLLER FEEDER

INDUCTANCE

for increased range of material thicknesses possible for welding

INDUCTANCE

for increased range of material thicknesses possible for welding

Quick Use Mode

auto parameter selection and 5

selectable languages on the LCD panel

FAN STOP MODE

FOR LOW NOISE

High efficiency Heavy Duty: 60% at 40°C; 198A

RESELLERS

iTECH MIG 280 4R

FULL SPECIFICATIONS

The iTECH MIG 280 4R 3-in-1 welder is primarily for use in light industry. With the innovative MIG/MAG AUTO system, once the material, thickness and wire diameter are entered, the unit selects optimal settings and is ready to go. It also has a MANUAL settings mode for metalshop masters and pro welders. Semi-Pro and amateur welders will never regret the iTech, since they can focus on their technique instead of the settings. The machine is on a rugged cart with swivelling castors and enough room for 50L cylinders to be safely moved.

The iTECH MIG 280 4R has an innovative system of air flow through the cooling chamber NorthernWind (NW), boosting the life, durability and duty cycle of the components.

Equipped with an enhanced 4R four-roll feeder for a smoother and stable wire feed, as well as connectors for 5m MIG torches, and room to fit a D300 wire spool. It has a 5″ LCD display, for intuitive and easy operation in 5 languages. It offers a comfortable, quiet operating mode (FAN STOP) that saves energy. Can weld any of 3 methods: (MIG/MAG-AUTO), electrode (MMA) and LIFT-TIG.

The iTECH MIG 280 4R is all about intuitive operation and advanced functionality, for individual adjustment of settings in PULSE, DUAL PULSE and INDUCTANCE technologies. The unit has a 3-metre all-copper 4×4 [mm2] 450V/750V power cable and a 3-metre all-copper 25 [mm2] ground cable. The kit includes a 3-metre electrode holder and a 4-metre KD24 torch.

The iTECH MIG 280 4R is ideal for welding materials with thicknesses from 0.5 [mm] to 23 [mm]:

- light industry (aluminium structures, stainless steel tanks),

- in the metalshop (welding of half-shafts, welding of balustrades),

- at home (repair of backhoe blades, manufacture of gates and fences).

Basic info about the SKANDI KRAFT iTECH MIG 280 4R

- PULSE and DUAL PULSE welding, for better transfer of the filler metal into the welding pool, boosting the quality and strength of the joint. The high welding current (280 A) and 400 V power supply is good for welding thicker structural elements.

- The welder comes with a 4 roller wire feeder, so the wire is fed smoothly and steadily as required. The redesigned feeder can connect long MIG torches.

- MIG/MAG AUTO system – after selecting the material, thickness and wire diameter the machine can auto adjust the welding parameters.

- Welder with an easy-to-read 5″ LCD display, five selectable languages and 18 memory channels to save your settings.

- Welds in 4 methods: MIG/MAG AUTO, MIG/MAG, LIFT- TIG and MMA.

- The FAN STOP system switches off the fan at idle so even a powered up and fully functional welder is silent, saves energy and attracts no dust. The fan automatically switches on when welding starts.

- Can connect a SPOOL GUN holder (with integrated wire feeder) for better material transfer to the weld.

- Lamp inside the welder for easy wire change in the wire feeder.

- Push button for quick wire ejection (inching).

- Welder on a sturdy cart with space enough for cylinders up to 50L. A chain to secure the cylinder and hooks for transporting the machine are included.

- The device adjusts the welding current in the LIFT-TIG method after setting the material thickness. In the MMA method, the device suggests the electrode diameter, together with the material thickness adjustment and intelligent parameter selection, .

- Convenient dials and a clear panel make it easy to set the welder up quickly, even when wearing welding gloves.

- Features 2T and 4T options to make longer welds more comfortable.

- SPOT functions designed for spot welding. The machine has a preset heat-up time and the operator just sets the welding current. This function is most commonly used in auto repair shops.

- Functions S_2T /S_4T combines two welding techniques. Spot welding, for shielding gas before and after the welding process. In addition, a 2T and a 4T are combined to create the S_2T/S_4 method, so welding starts and stops correctly.

- It is built with high performance IGBT components.

- Gas heater connector (36 V) – use the socket to connect the regulator with the heater or the heater itself and heat the gas to a positive temperature.

Welder functions

MIG/MAG AUTO welding

- The automatic setting of the welder: after specifying the material and thickness; and diameter of the wire, the machine adjusts toe optimal welding parameters. Manual fine-tuning of the welding current lets you adjust the parameters individually.

- Choice of 4 welding methods, brazing option.

- PULSE welding, for better transfer of filler material into the weld pool, boosting the quality and strength of the joint.

- Choice of 2T/4T, for making longer welds in better comfort.

- Choice of weld material (Carbon steel, Stainless steel, Al-S – soft aluminium, Al-Mg – hard aluminium, Cu-Si – brazing).

MIG/MAG welding

- PULSE welding, for better transfer of filler material into the weld pool to boost the quality and strength of the joint.

- 2T/4T selection, so longer welds are made in better comfort.

- SPOT welding functions and S_2T and S_4T welding support, i.e. gas shielding before the welding process from a lower current to base current and finally lowering the current to the crater quench setting and using gas shielding until the process is completed.

- Welding material selection (Carbon steel, Stainless steel, Al-Si – soft aluminium, Al-Mg – hard aluminium, Cu-Si – brazing).

- Selection of weld material thickness.

- Determination of wire diameter. In Al-Si and Al-Mg (range 1.0-1.2 [mm]), other materials from (0.8-1.2 [mm]).

- Setting of wire feed speed [m/min].

- Welding current voltage setting [V].

- Adjustment of inductance ± [%].

- Pulse frequency setting in pulse mode [Hz].

- Pulse cycle adjustment [%].

MIG/MAG DUAL PULSE welding

- Peak feed speed [m/min].

- Base wire feed speed [m/min].

- Adjustable double pulse frequency [Hz].

- Adjustable double pulse duty [%].

MMA welding

- Hot Start – temporary boost in the welding current for better performance.

- Arc Force – adjusts the welding arc length, to reduce or increase the depth of fusion and reduce spatter.

- VRD – turns off the arc when the electrode detaches from the material for a safer welding environment.

- Anti Stick – easier electrode detachment in the event of sticking.

LIFT-TIG welding

- Adjustable welding current [A], once set the welder prompts the thickness of the sheet metal.

- The LIFT-TIG function is equipped with a SOFT START module, for no risk of damaging the electrode when starting the welding process.

Can return to factory settings by holding the “Return” button.

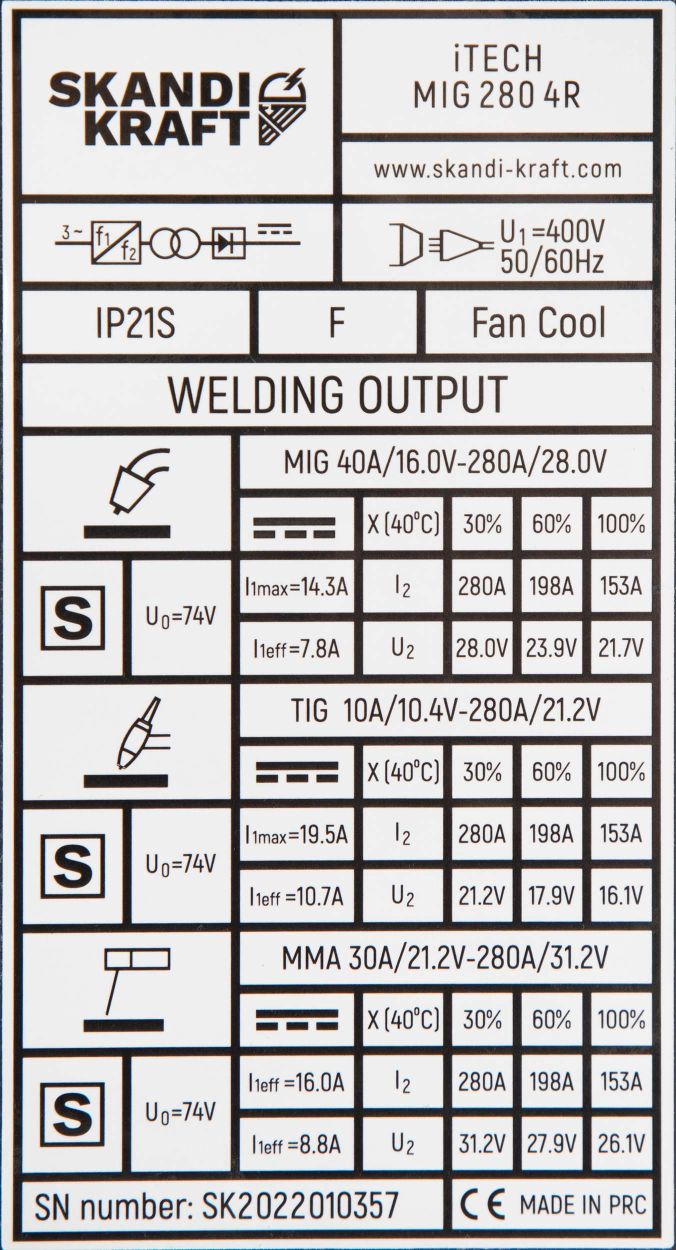

POWER SUPPLY PARAMETERS

- Power supply: 400 V

- Frequency: 50/60 Hz

- Idling voltage: 74 V

TECHNICAL PARAMETERS

- MIG welding current: 40-280 A

- MIG welding voltage: 16-28 V

- MIG efficiency (at 40°C):

- 30%/280 A/28 V

- 60%/198 A/23.9 V

- 100%/153 A/21.7 V

- TIG welding current: 10-280 A

- TIG welding voltage: 10.4-21.2 V

- TIG efficiency (at 40°C):

- 30%/280 A /21.2 V

- 60%/198 A/17.9 V

- 100%/153 A/16.1 V

- MMA welding current: 30-280 A

- MMA welding voltage: 21.2-32 V

- MMA efficiency (at 40°C):

- 30%/280 A/31.2 V

- 60%/198 A/27.9 V

- 100%/153 A/26.1 V

- Feeder: 4 R

- Wire spool diameters: D200, D300

- Maximum spool size: 5 [kg], 16 [kg]

- Wire diameter for use in the welding machine: 0.8/1.0/1.2 [mm].

PHYSICAL SPECIFICATIONS

- Length x width x height of the welder with cart when the unit is folded: 89 × 51 × 81 [cm].

- Length x width x height of packaging, inside set with cart: 74 × 43 × 90 [cm].

- Weight of unit: welder [net] 49 [kg], in box [gross] 62 [kg]

- Degree of housing protection: IP21S

- Cooling: fan

ADDITIONAL FUNCTIONS

- 4-roll wire feeder for smooth filler material transfer: yes

- PULSE and DUAL PULSE for better quality welding: yes

- FAN STOP – switching off the fan when not in use: yes

- Connection for quick-connect gas hose (TYPE 21): yes

- Gas heater connection: yes

- SPOOL GUN external wire feeder connection: yes

- VRD voltage reduction and safety improvement: yes

- Arc Force welding arc length control: yes

- Hot Start rapid arc ignition: yes

- Anti sticking electrode: yes

- Cart: yes

- Memory channels: 18

- SKANDI KRAFT iTECH MIG 280 4R welder with integrated 3-metre 4×4 [mm2] power cable

- MIG welding holder MB 24 4-metre with Teflon-graphite insert

- Additional blue steel insert 4 m for MB 24 holder for welding with 0.8 -1.0 [mm] wire diameter

- All-copper electrode holder 3 metres, cross section 25 [mm2]

- Wire rollers: for aluminium 2x 1.0-1.2U, for carbon steel 2x 0.8-1.0V

- Wire feeder rollers size 22/10/30 [mm]

- Gas cylinder mounting components: 2 x gas regulator mounting clamps, 2-metre gas hose, spanner, Allen key

- Current pins for handle KD24, MB24 (1x 0.8; 1×1.0; 1×1.0 ALU; 1×1.2 ALU)

- Bushing with spring for guiding the welding wire to the feeder.

- Instructions.