Versatile and rich functionality for the metalshop and home

SKANDI KRAFT®

iSimple MIG 215

iSIMPLE MIG 215 Welder

Powerful iSIMPLE MIG 215 welder with a convenient panel and extensive functionality, including brazing. It has a synergic parameter setting option. Its compact size, 14.6 [kg] weight and transport handle, make it mobile and convenient to use. It offers a comfortable, quiet operating mode (FAN STOP) to save energy. For welding with 3 methods, either with gas cylinder (MIG/MAG) or without gas (FLUX); electrode (MMA) and LIFT-TIG.

The iSIMPLE MIG 215 is ideal for welding materials with thicknesses

from 0.5 [mm] to 12 [mm]:

- in metalshop work (stainless steel handrails, light agricultural equipment),

- in your home (pantry racks and bike rack),

- in your company (bodywork repairs, soldering, assembly work).

DIGITAL PANEL WITH 5 SYNERGY PROGRAMS

DIGITAL PANEL WITH 5 SYNERGY PROGRAMS

MOBILE WELDING MACHINE WITH CARRYING HANDLE

TWO-ROLLER WIRE FEEDER

TWO-ROLLER WIRE FEEDER

SINGLE AND DUAL PULSE

for better results and performance

SINGLE AND DUAL PULSE

for better results and performance

FAN STOP MODE for low noise

High efficiency Heavy Duty: 60% at 40C; 200A

RESELLERS

iSIMPLE MIG 215

FULL SPECIFICATIONS

Powerful iSIMPLE MIG 215 welder with a convenient panel and extensive functionality, including brazing. It has a synergic parameter setting option. Its compact size, 14.6 [kg] weight and transport handle, make it mobile and convenient to use. It offers a comfortable, quiet operating mode (FAN STOP) to save energy. For welding with 3 methods, either with gas cylinder (MIG/MAG) or without gas (FLUX); electrode (MMA) and LIFT-TIG.

The iSIMPLE MIG 215 is all about simplicity of use and advanced synergic functions: (FE), (SS), (AlSi/AlMg), brazing (CuSi) and technological functions: PULSE and DUAL PULSE.

The unit has a 3-metre all-copper 3×2.5 [mm2] power cable and a 3-metre all-copper 25 [mm2] ground holder. The kit includes a 3-metre electrode holder and a 4-metre KD24 holder.

The iSIMPLE MIG 215 is ideal for welding materials with thicknesses

from 0.5 [mm] to 12 [mm]:

- in metalshop work (stainless steel handrails, light agricultural equipment),

- in your home (pantry racks and bike rack),

- in your company (bodywork repairs, soldering, assembly work).

Basic information about the SKANDI KRAFT iSIMPLE MIG 215

- Welder with rich functionality and synergic welding option, soldering is also possible.

- For welding with 3 methods: MIG/MAG, LIFT-TIG and MMA

- It has the PULSE( 1P) and DUAL PULSE (2P) option.

- Has 4 synergy programmes: for black steel (FE), stainless steel (SS), aluminium (AlSi/AlMg), brazing (CuSi).

- High productivity: 60% duty cycle at 200 A at 40 degrees C

- Can connect a SPOOL GUN holder (holder with integrated wire feeder) for improved material transfer to the joint.

- The FAN STOP system switches off the fan at idle – so that the welder, when powered up and fully functional, makes no noise, saves energy and reduces dust in the system. The fan automatically switches on when welding starts.

- Convenient dials and a clear panel for quick adjustment of the welder, even when wearing welding gloves.

- When welding [MMA], the VRD function turns off the arc when the electrode detaches from the material for a safer welding environment.

- It has 2T and 4T options, for longer welds to be created more comfortably.

- The ability to adjust the inductance, to reduce the amount of spatter and allow efficient soldering.

- It’s built with highly efficient IGBT components.

- Gas preheater connector (36 V) – by using the socket, it’s possible to connect a regulator with the preheater or the preheater itself and heat the gas to a positive temperature.

Welder functions

- Choice of 3 welding methods, brazing option.

- Choice of 2T/4T, which enables longer welds to be made more comfortably.

- PULSE and DUAL PULSE welding, which improves the transfer of filler material into the weld pool with particular effect on the quality and strength of the weld.

- VRD for MMA welding.

- REM – remote control function.

MIG/MAG welding

- 4 selectable synergy programmes ( FE – carbon steel, SS – stainless steel, Al-Si – soft aluminium, Al-Mg – hard aluminium, Cu-Si brazing).

- Selection of the inductance value, to reduce spatter, influence the width of the weld, the regulation of the hardness of the arc and is used in soldering.

- Setting of pulse frequency in PULSE mode [Hz].

- Adjustable pulse cycle [duty].

- Choice of three wire diameters: 0.8; 1.0; 1.2 [mm].

- Wire feed speed setting (1.5-12 [m/min]).

- Adjustable basic current and peak current in 4T mode.

- [A diode].

LIFT- TIG welding:

- Adjustable welding current [A].

- TIG- LIFT function equipped with SOFT START module, for no risk of damaging the electrode when starting the welding process .

MMA welding

- Adjustable welding current [A].

- VRD – turns off the arc when the electrode detaches from the material for a safer welding environment.

For factory reset, just hold down the “menu” button.

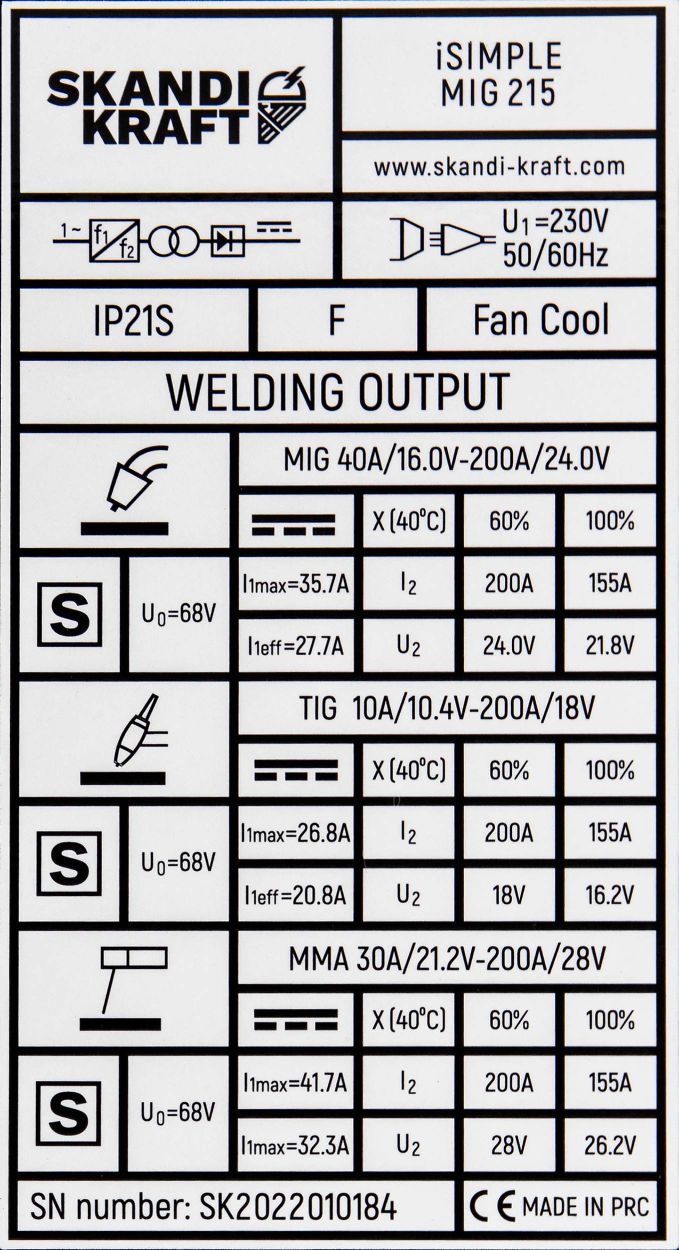

POWER SUPPLY PARAMETERS

- Power supply: 230 V

- Frequency: 50/60 Hz

- Idling voltage: 68 V

TECHNICAL PARAMETERS

- MIG welding current: 40*-200 A

*parameter averaged min. current 20 [A].

- MIG welding voltage: 16-24 V

- MIG efficiency (at 40°C):

- 60%/ 200 A/24 V

- 100%/ 155 A/21.8 V

- TIG welding current: 10-200 A

- TIG welding voltage: 10.4-18 V

- TIG efficiency (at 40°C):

- 60%/ 200 A/18 V

- 100%/ 155 A/16.2 V

- MMA welding current: 30-200 A

- MMA welding voltage: 21.2-28 V

- MMA efficiency (at 40°C):

- 60%/ 200 A/28 V

- 100%/ 155 A/26.2 V

- Feeder: 2 R

- Wire spool diameters: D200

- Maximum spool size: 5 [kg]

- Wire diameter for use in the welding machine: 0.8/ 1.0/ 1.2 [mm].

PHYSICAL CHARACTERISTICS

- Length x width x height: 48 × 21 × 38 [cm].

- Weight: welding machine [net] 14.6 [kg], in a carton [gross] 21 [kg]

- Degree of protection of housing: IP21S

- Cooling: fan

ADDITIONAL FUNCTIONS

- PULSE and DUAL PULSE – more quality welding: yes

- FAN STOP switching off the fan at rest: yes

- Connection for quick-connect gas hose (TYPE 21): yes

- Gas heater connection: yes

- SPOOL GUN external wire feeder connection: yes

- VRD voltage reduction and better safety: yes

- Memory channels: 18

- SKANDI KRAFT iSIMPLE MIG 215 welder with integrated 3 m 3×2.5 [mm2] power cable

- MIG torch KD24 type MB24 4 metres with Teflon graphite insert

- Additional blue steel insert 4 metres for KD24 holder, for welding with wire of 0.6 -1.0 [mm] diameter

- All-copper electrode holder 3 metres, cross section 25 [mm2]

- Electrode holder all-copper 3 metres, cross section 25 [mm2]

- Wire rollers: for steel 1x 0.8-1.0 V, for aluminium 1x 1.0-1.2 U

- Wire feeder rollers size 22/10/30 [mm]

- Gas cylinder mounting components: 2 x gas regulator mounting clamps, 2 metre gas hose, spanner, Allen key

- Current tips for KD24, MB24 torch (1x 0.8 ; 1×1.0 ;1×1.0 ALU; 1×1.2 ALU)

- Instructions